Free next working day delivery if ordered by 2pm

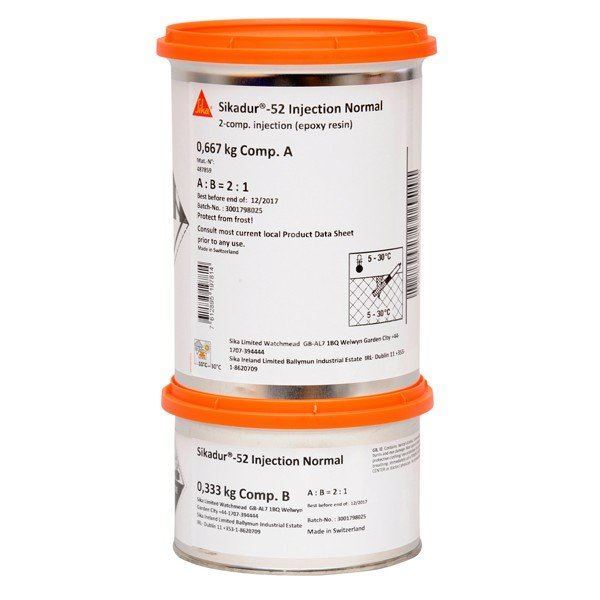

Sikadur 52 Injection Type N

Sikadur 52 Injection Type N is a two part, solvent-free, low viscosity injection-liquid, based on high strength epoxy resin.

Type N (= Normal Potlife) is used for substrate temperatures between +5°C and +30°C (UK).

As an injection resin with good adhesion to concrete, mortar, stone, steel and wood.

Sikadur 52 Injection Type N is used to fill and seal voids and cracks in structures such as bridges and other civil engineering buildings, industrial and residential buildings, e.g. columns, beams, foundations, walls, floors and water retaining structures. It not only forms an effective barrier against water infiltration and corrosion promoting media, but it also structurally bonds the concrete sections together.

- Solvent-free

- Suitable for both, dry and damp conditions Usable at low temperatures

- Shrinkage free hardening

- High mechanical and adhesive strengths

- Hard but not brittle

- Low viscosity

- Injectable with single component pumps